Technology and craftsmanship behind rubber processing

Aug 12,2025

At Dalian Bohai Rubber and Plastics Co., Ltd., mixing engineers are indispensable technical core members in the production process of rubber products. They are like "rubber magicians", transforming various raw materials into high-performance rubber compounds through precise formulas and processes, laying the foundation for subsequent products.

Unveiling the Quality Code within Rubber through Mooney Viscometry

Aug 12,2025

Pushing open the door to the Bohai Rubber Testing Laboratory, a serious and focused atmosphere permeates the air. From today onwards, we will gradually get closer to the "unsung heroes" who safeguard product quality—the professional equipment in the laboratory. At this moment, the lens is focused on a machine in operation. The technician's hands steadily operate the machine, which is the subject of our discussion today: the Mooney viscometer.

May 29,2025

This process includes basic procedures such as plastication, mixing, calendering or extrusion, molding, and vulcanization. Each procedure has different requirements for the product and is supported by several auxiliary operations.

Introduction to the main properties of rubber

May 29,2025

When selecting rubber materials, the first consideration should be the operating environment (temperature, medium) and working conditions (stress, vibration) of the part. This is the basic principle for selecting the type of rubber material. Secondly, after the rubber type is defined, it is necessary to examine whether the material properties meet the requirements. The following introduces the main performance evaluation items of rubber materials.

Apr 29,2025

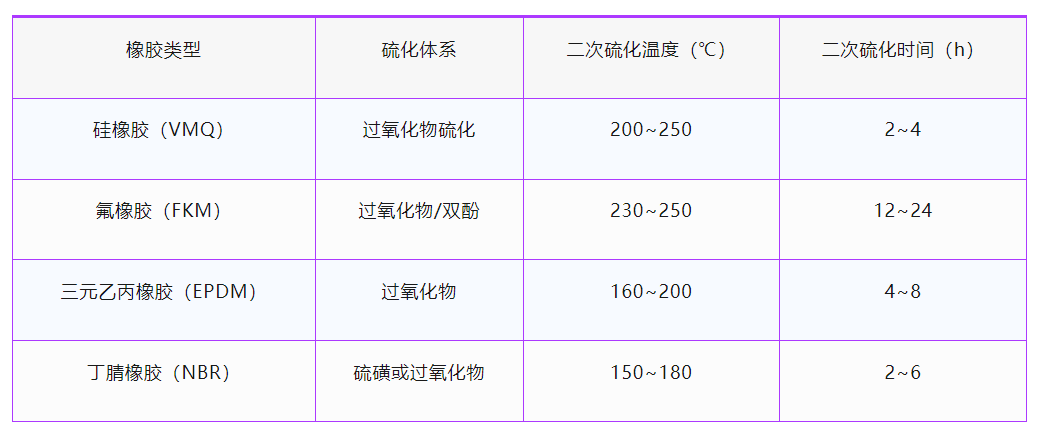

Rubber vulcanization is a process that transforms linear or branched rubber molecules into a three-dimensional network structure through chemical crosslinking, thereby improving the mechanical properties, heat resistance, and chemical corrosion resistance of the rubber. However, in some applications, single vulcanization is insufficient to meet the performance requirements of the final product, necessitating a post-cure or secondary vulcanization. This article will elaborate on the circumstances under which rubber requires secondary vulcanization, analyze its advantages and disadvantages, and discuss influencing factors.

The function of the rubber intake pipe

Dec 13,2024

The main function of the excavator's intake pipe is to increase the engine's output power, providing greater power to the main pump, thereby allowing the excavator to achieve higher work efficiency.