Dalian Bohai Rubber & Plastic Co., Ltd. in its field

Sep 30,2025

Dalian Bohai Rubber & Plastic Co., Ltd., as a pioneering domestic supplier of high-performance rubber materials, boasts a comprehensive R&D-production-quality inspection-service system. The company is equipped with advanced laboratories and production lines, dedicated to meeting the specialized demands of industries such as automotive, electronics, and medical fields—specifically in areas like high- and low-temperature resistance, media resistance, sealing performance, biocompatibility, and conductive/insulating properties.

Sep 30,2025

The core equipment in the field of sample testing— the computerized rotorless vulcanometer. It’s like equipping the vulcanization process with a pair of "keen eyes," using innovative design and precise monitoring to completely transform the limitations of traditional testing methods.

Sep 26,2025

To comprehensively enhance the company’s on-site management practices, create a clean, standardized, safe, and efficient working environment, and cultivate employees’ strong professional ethics—thereby effectively boosting productivity, ensuring product quality, and reducing operational costs—the company’s management recently decided to fully implement the 5S on-site management system—centered around "Sort, Set in order, Shine, Standardize, and Sustain"—across the entire organization. This marks a crucial and solid step forward for the company on its journey toward refined and standardized management.

Company leaders emphasized: "Adopting the 5S management approach is an inevitable choice as we strive to become a more disciplined and highly efficient enterprise. This initiative isn’t just the responsibility of management—it’s also the shared mission of every Bohai employee. Let’s take proactive action together, using our collective efforts to build a workplace that inspires pride and fosters growth. Together, let’s move forward hand in hand and achieve outstanding success!"

Notice Regarding the Company's 2025 National Day Holiday Arrangement

Sep 25,2025

Notice on the Company’s 2025 National Day Holiday Arrangements

Issued by: Dalian Bohai Rubber & Plastic Co., Ltd.

Date of Release: September 25, 2025

As the golden autumn brings refreshing breezes and the sweet fragrance of osmanthus fills the air, we are soon to celebrate the 76th anniversary of the founding of the People’s Republic of China. In accordance with national regulations regarding statutory holidays and considering our company’s specific circumstances, the 2025 National Day holiday arrangements are hereby announced as follows:

Sep 25,2025

Due to tight supply, Vietnamese rubber prices remain relatively strong, prompting cautious purchasing behavior among downstream buyers. On September 8, the spot price of natural rubber reached 15,416 yuan per ton, marking a weekly increase of 3.06%. Meanwhile, inventories in the Qingdao region fell by 1.66% from the previous week, standing at 592,300 tons, while raw material prices continued to stay high. From January to August 2025, Côte d'Ivoire's natural rubber exports totaled 1.05 million tons, up 14.4% compared to the same period last year. Although export volumes rose year-on-year in August, they declined on a monthly basis as the country continues to adjust its planting structure. In the first half of 2025, the rubber tire industry generally experienced a situation where revenues increased but profits did not—nine companies saw revenue growth, yet their profitability slipped.

Sep 24,2025

Mixing is a critical process in rubber product manufacturing, aimed at uniformly blending raw rubber with various compounding agents—such as fillers, vulcanizing agents, accelerators, and antioxidants—through mechanical shearing. This process produces a compounded rubber that meets specific performance requirements. The quality of the mixing process directly influences both the processing characteristics of the rubber compound and the final physical and mechanical properties of the finished product. This article provides a detailed introduction to the working principles and procedures of both internal mixers and open mills.

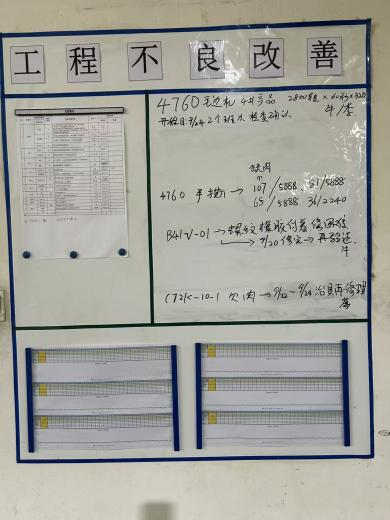

Manufacturing Defect Improvement Initiative

Sep 24,2025

Recently, a dedicated improvement team has been established to address long-standing production issues—primarily focusing on products with high defect rates. The team comprises members from departments such as technology, manufacturing, and quality inspection. They hold daily meetings to discuss these challenges, propose targeted improvement measures, assign clear responsibilities, and systematically track and verify the effectiveness of both the improvements and their implementation. The goal is to reduce the defect rate of these persistently problematic products back within the specified acceptable range—and to ensure that continuous improvement efforts can be sustained over time.

Causes and Prevention of Rubber Product Blooming

Sep 24,2025

Scorching refers to the phenomenon where compounding agents in rubber products—such as sulfur, accelerators, antioxidants, plasticizers, zinc oxide, and others—exceed their solubility limit within the base rubber. Alternatively, these agents may migrate to the surface of the product over time due to mechanisms like migration or phase separation, gradually forming a white, frost-like deposit on the material's surface.