Products

Production and processing of auto parts, with more than 30 years of experience in automobile production

Meet Customer Needs, Product Quality And Exquisite

Dalian Bohai Rubber Plastics Co., Ltd., located in the beautiful coastal city of Dalian, was founded in 1984. Since its establishment, the company has been engaged in the production and processing of auto parts, and has more than 30 years of experience in automobile production. The company adheres to the business philosophy of "integrity-based, innovation as the soul, continuous transcendence, and pursuit of perfection". The supporting industries are involved in the field of automotive rubber, construction machinery, household appliances, etc., and the product series involves rubber parts, plastic parts, stamping parts, Die-cutting parts, etc.

In line with the policy of continuous optimization of product quality and continuous improvement of management system, the company passed the ISO9001 quality system certification in 1997, the TS16949 quality system certification in 2007, the IATF16949 quality system certification in 2017, and the VDA6.3 audit of BAIC Group in 2018.

-

2015

年公司成立于2015年

-

10

+服务领域10+

-

100

+各类合作项目100+

-

1000

+1000+合作客户

-

99

%+客户满意度99%+

Time of establishment

Floor Area

Product matching experience

Existing staff

service satisfaction

Automobile Industry

Automobile Industry

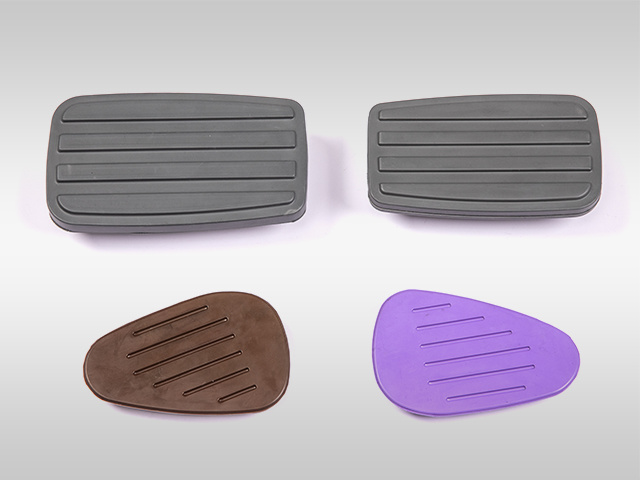

Hole Plugging Limit Block Lifting Lugs Harmonic Block Bushing Water Pipe

Construction Machinery

Construction Machinery

Bushing Sheath Hole Plugging Dust Boot Air Pipe Bellows

Mechanical Electrical

Mechanical Electrical

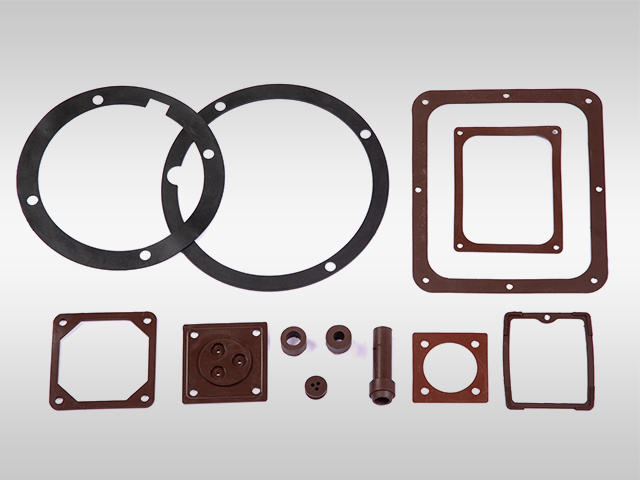

Gasket

Semiconductor

Semiconductor

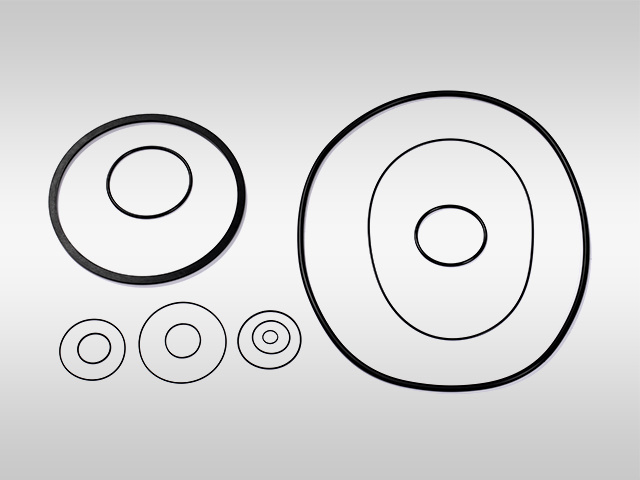

Seal Ring Standard Sealing Ring Agent Devibration Station Agent

Absorbing Rubber

Absorbing Rubber

Tablet Hollow Cone

Construction Industry

Construction Industry

Anti-Vibration Rubber

Partners

Supporting industries involved in the field of automotive rubber, engineering machinery, household appliances, etc., product series involving rubber parts, plastic parts, stamping parts, die-cutting parts.

Company News

Horses of the Sea, Shaping the Future—2026 Bohai Annual Conference

Feb 13,2026

Company News

Feb 13,2026

Company News

Dalian Bohai’s Holiday Notice for the 2026 Spring Festival

Feb 04,2026

Product knowledge

Feb 04,2026